Color is everywhere and in the print world it’s everything.

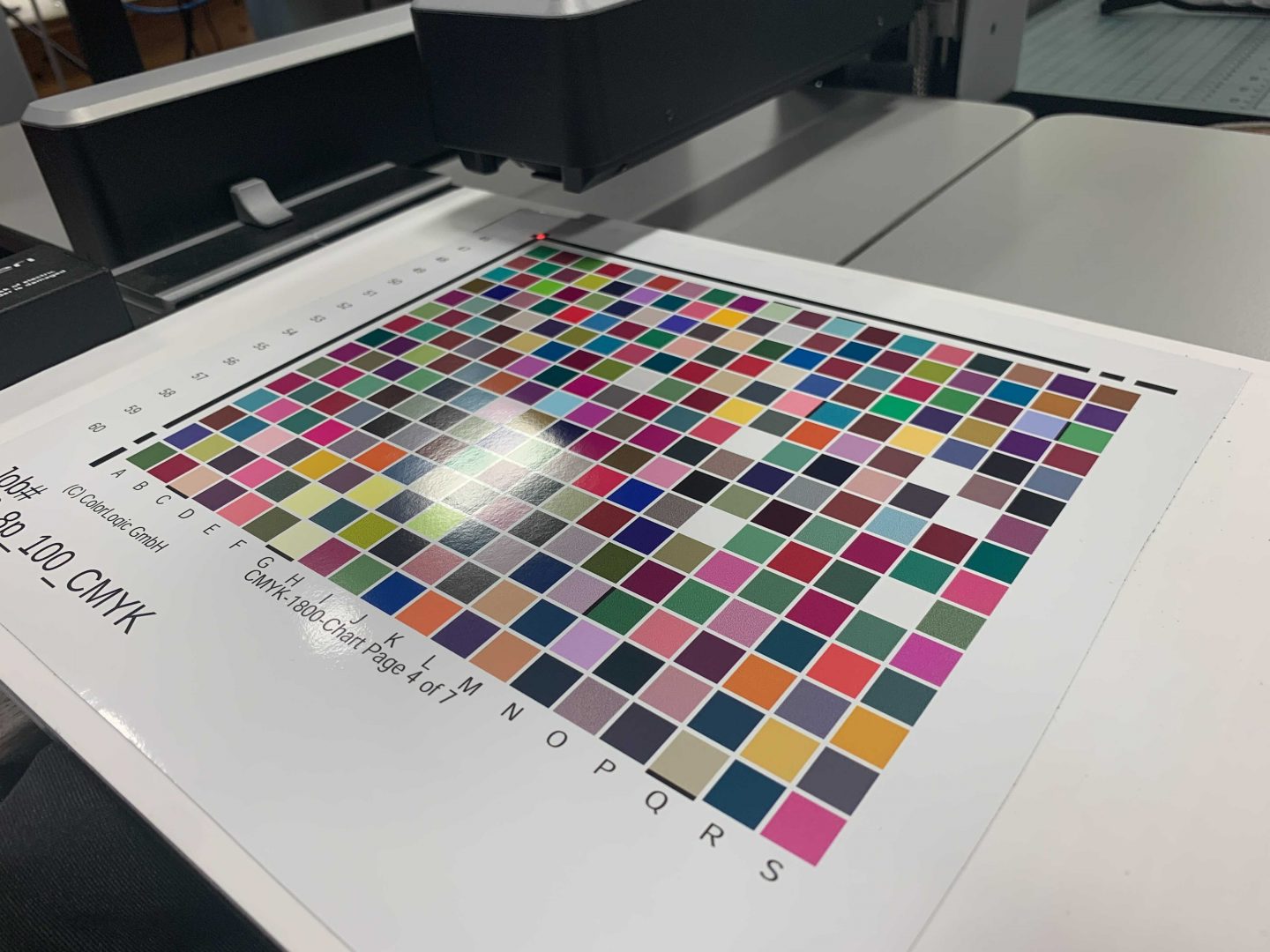

It seems there are endless options when it comes to printing colors. To make matters worse, a job often calls for accurate reproduction of color from a variety of printers across multiple materials. Seifert Graphics recently became certified as a G7 Master Grayscale Facility, which means we know what we are doing when it comes to consistent color production (and we can prove it). We sat down with Dan Reid of RPImaging, the gentleman that helped us achieve our certification. We asked him a few questions regarding color, the management of color, and why print customers should seek a print vendor certified as a G7 Master Facility.

Below is that interview. So, get yourself a nice, hot cup of CMYK (29,60,71,52) and enjoy our conversation with Dan!

Q: Let’s start off with who you are and what you do.

A: I’m Dan Reid from RPimaging and I help printing companies with color consistency and color matching. I work with companies across the US, though I am based in Arizona.

Q: In your experience, what is digital color management?

A: Digital color management is a way to communicate color intentions from inception all the way to actual production.

"Digital color management is a way to communicate color"

Q: Why is digital color management important?

A: Without being able to communicate properly there’s usually a breakdown between the different entities where colors are not being correctly communicated, so the expectation is different. Using color management allows us to have a continued communication from design inception all the way out to production.

Q: How will a customer feel the effects of proper versus improper color management?

A: When people have properly implemented color management, there’s usually no discussion about color. When improperly, there’s usually a lot of discussion that comes up. It’s usually because the expectation has been set incorrectly. So that’s when it fails or why it’s successful.

Q: What are the limitations of digital color management in your experience?

A: Mainly it’s due to limitations of pretty much the printing devices. Every printer and ink combination has a finite range of colors that can be printed. So, sometimes the expectation up front is greater than what the actual production devices can do.

Q: And that’s usually comparing different printing media to paint or to offset versus a digital or screen printing. Correct?

A: Yeah. I mean, they all have different ways of reproducing color and each one of those has different color ranges that are bigger or smaller. When that fails, people have the expectation of “A” but really the device is only capable of printing “B”.

Q: What is the importance of lighting?

A: Lighting is one of the things that’s not discussed enough. When evaluating color, you are perceiving color based upon you, the observer, the actual object, and the light source. Change any of those three things and you’ll perceive color differently. The printed object doesn’t change but you may see color differently in the morning than later in the day when you’re tired. If you move that print to a different light source, you may not be changing, but the light source may change your perception of color.

"Lighting is one of the things that's not discussed enough."

Q: What are the downsides of improper lighting?

A: Miscommunication of color. A client thinks one thing and what’s actually being printed is something different just because they’re evaluating under different lighting conditions.

Q: How would I know if I have proper lighting to judge color with?

A: There’s different levels to this, but a very basic level is something that’s called a RHEM indicator strip. This is a sticker that you put on the back of the print or proof, and if you can see bands in it, then that means that the lighting you’re looking at is not correct. If you don’t see any bands then it means you’re looking under the correct light. It’s kind of loosey goosey but it’s better than nothing. It’s a way for people to start a conversation about lighting, cheaply.

Q: How should a customer, the end user of a product, communicate their color needs and expectations to their print vendor?

A: It really starts with a conversation with the print vendor and finding out what they would prefer to have. A Print Service provider usually can communicate pretty clearly what they want, “Hey, I want to see CMYK files, or I want spot colors and I don’t want this, I want that”. That’s going to be the best for the client, because then they’re properly setting up the files at the beginning that the print vendor really needs.

Q: What should customers expect from print vendors?

A: Well, we have used a tool called a contract proof. What this is setting the expectations, saying, here’s what the color is going to look like on our devices. The client then looks at that, either signs off on it or says “No, I’m not happy with that color.” Once the client signs off on that proof, now there is an expectation that the printer can actually match that proof because that’s what’s been agreed upon. Sometimes they sidestep that and make an on-press proof, which means they don’t use a proofing system. They literally go to the press and print out and get the client to sign off on that, and say “this is what you’re about to buy.” That’s the way to properly set the expectations so there isn’t a miscommunication upon delivery.

Q: What is G7 Master Certification?

A: The G7 Master Printer program was designed to have a way to evaluate our printer output to have a similar color appearance across their printing technologies. This is a calibration method that allows you to get a similar look, but not a color match, on different types of printing technologies. If you’re a print buyer or a brand owner, and you were to find a company that is G7 certified you’d have a better chance of having your product look the same across different print vendors than using print vendors that were not G7 certified.

Q: How does one find G7 certified print manufacturer?

A: There is a special website for G7, but the easiest way to find it is to go idealliance.org then search for G7 master printer, and they’ll have them up there.

Q: Last question I have for you, how does someone get ahold of you for their own color management implementation?

A: You can reach me at my website rpimaging.com or our phone of (866) RGB-CMYK. Thanks.

You must be logged in to post a comment.