Ever since the early 90s there was a push in the transit industry for lighter (better fuel economy), graffiti resistant (nasty vandals), and cheaper (we love saving money) plastics for use on the interior of buses and trains. Many of the plastics used today are composed of PVC or acrylics and are textured.

Sounds awesome, but why should you care?

Well, standard adhesives that are used in the transit graphic industry just do not like to stick to these types of plastics. You may get lucky, but chances are in a few weeks, the interior decals of your vehicle will look really sad and attempt to jump ship.

So, what do you do when your decals don’t stick on the inside of a vehicle?

There are two solutions:

- Riveted aluminum plates

- An adhesive that is strong enough to grab hold and never let go.

Riveted aluminum plates are considered a life of vehicle product. They are great for customers that never want to replace or maintain the safety messaging on the inside of a vehicle. They will never chip, crack, fade, get picked at or peel! Sign me up! Right?

Well, one of the draw backs is that aluminum plates aren’t the cheapest. The other? Since they are being riveted, no components can be on the opposite side of the panel you are affixing the plate to. Neither are deal breakers and we do have a number of customers that prefer aluminum plates over the alternatives.

Strong adhesives are considered non-removable adhesives. That means, when they are stuck…they are really stuck. They even remain stuck to those textured plastics. Sure, you can remove them, but it’s going to take a lot of effort and they are going to leave a significant adhesive residue behind with them.

We always recommend using Vigor since, well, do I really have to say it? It’s been used for the past 10 years with great success in the field where other adhesives didn’t have the power to hang. Here’s the best part:

Vigor is no more expensive than the standard adhesives.

Remember! We all love saving money!

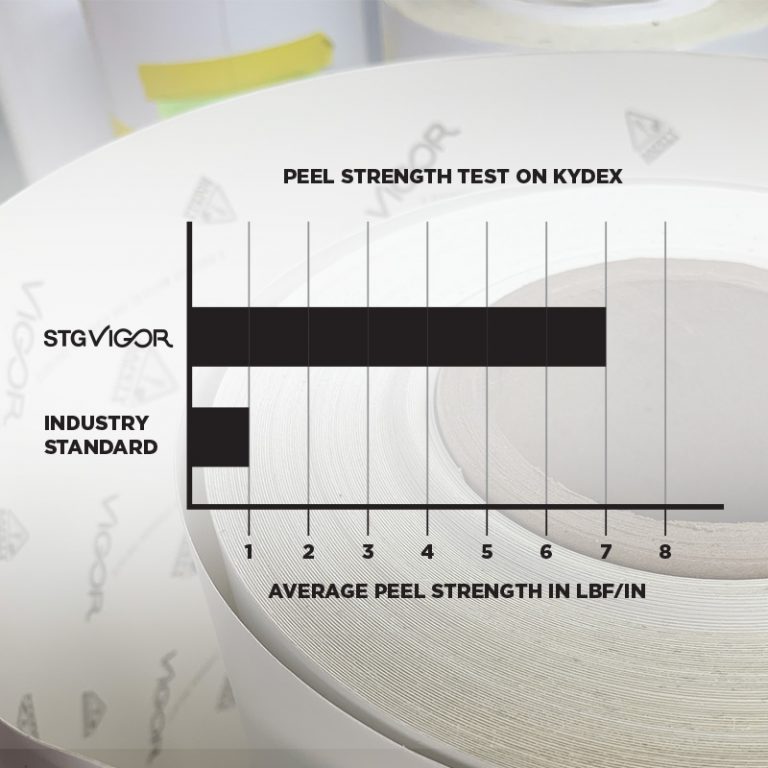

Kydex, a commonly used material on the interior of buses was used as the testing substrate and ASTM D903-98(2017), Standard Test Method for Peel or Stripping Strength of Adhesive Bonds (blah, blah, blah) was used as the testing standard. The report concluded that Vigor is on average seven times stronger than the industry standard adhesive when applied to textured Kydex.

Have you ever had a decal that can’t hang? Tell us about it in the comments!

You must be logged in to post a comment.